Starting the cabinet

I previously mentioned, I was waiting to start on the cabinet until I had obtained legs. Not having a lathe, or the skills to learn how to use one in a reasonable amount of time, I made contact with someone with a local wood turners group who agreed to make the legs for me at a very fair price. Given that I do not know anyone with a B3, it was pretty tough finiding exact measurements or anything that could resemble a template. After a lot of forum searching, I was finally able to give some really bad instructions on what should be made.

Given that these are hand-made one at a time, I’m extremely happy with the results. Since they need to hold over 300 pounds, we decided to go with maple.

All of this being said, it is time to get started on the cabinet!

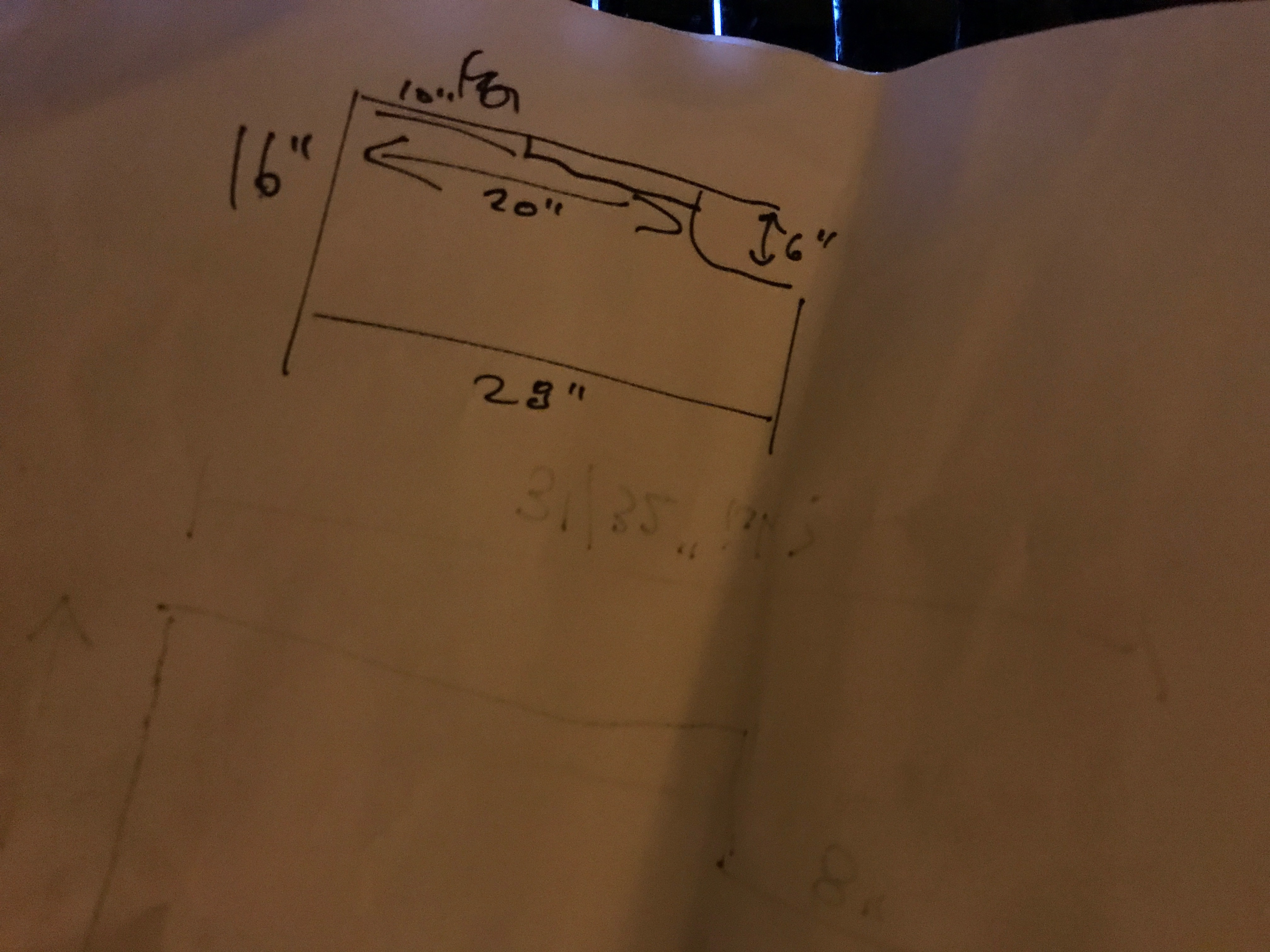

I’m a “wing it” kind of wood worker. I don’t think I’ve ever really used plans before. I took a tape measure to a friends BB Chop, so this is the closest thing to plans as I have.

I’ve decided to use 3/4” plywood on the bottom, and 1/2” everywhere else. On the sides I glued two pieces of 1/2” together to give me 1”. For the finish, I’m going to do a “piano black”, so I’m not all that concerned about having super high-grade cabinet plywood. I got everything I need a Home Depot for about $125.

My motto on stuff like this is “I have absolutely no idea what I’m doing”. That being said, I decided to counter sink a bunch of screws and glue the sides to the floor of the cabinet.

I want the instrument to look like a B3, but it is important to me that this is portable. So I routed out pockets in each side to install some handles. I haven’t run a router in over a year, so yeah…don’t judge me :)

I also forgot how filthy you get when routing.

For this project, I’ve decided to use Bondo to fill the screw holes and smooth out the plywood edges. So far, things are looking pretty good. I have a few more applications & sanding down to do, but at this point it is really smooth and I don’t think it’ll show up.

Not having plans, I’m going to dry fit everything into the case to finish a few last few things like setting the manual height. There is still the angled piece on the bottom that covers the bottom of the lower manual I need to figure out.

I’m experimenting with my plans for the final finish. I’ll write about it once I decide what to do. I’m currently going between lacquer (easy to fix issues) and some kind of car paint. I also need to do some writing about my issues when dropping the instrument back in the A100 case and getting next to no volume. If I wrote about it now, it would just be me complaining. Once I figure it out (likely when the case is done), I’ll explain what I figure out.

For some good news, I got my Nord Electro working with my Leslie. The cable is pretty gnarly and frankly dangerous at this point. As good as the leslie emulator on the electro is, you just can’t beat the real thing.